About Us

The Parker Aerospace Exotic Metals Forming Division is a world leader in the design and manufacture of innovative and technically demanding sheet metal fabrications for complex aerospace applications.

Working at Exotic is about being part of a team, a culture, something that is bigger than each of us individually. We began as a small group of people passionately committed to a common goal. That is why we are so proud of everyone in our Exotic family who strives to be the best at what they do every day, working as a collaborative team in a culture of continuous improvement to stretch the bounds of creative thinking and provide quality products to our customers around the globe.

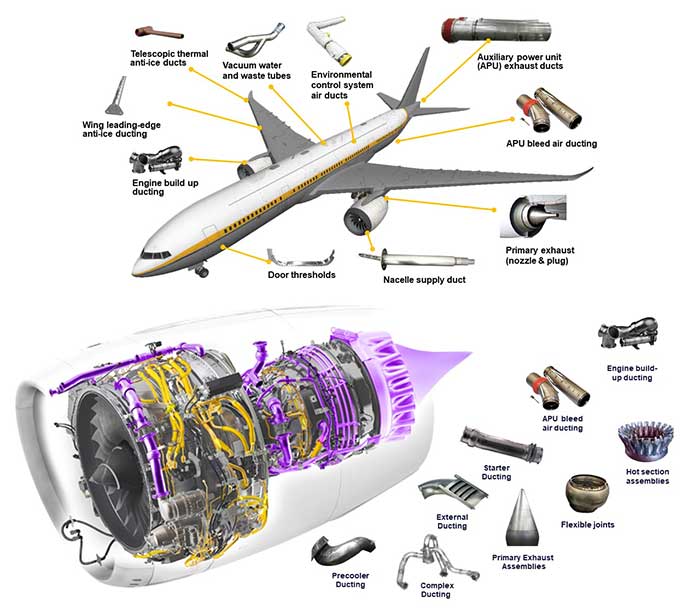

Exotic Metals has three advanced manufacturing facilities in the United States. The Kent, Washington, facility is the division headquarters and provides complex metal forming, complex metal fabrication, flexible joints, exhaust products, ducting products, plus repair and overhaul services. The facility in Airway Heights, Washington, provides complex metal fabrication, flexible joints, auxiliary power unit (APU) exhaust ducts, and other ducting products. The facility in Phoenix, Arizona, specializes in complex metal fabrication.

Exotic is proud to be recognized as an industry leader for manufacturing quality and performance, technical innovation, and delivering the right solution for its customers on time, every time. Engineering at Exotic is uniquely positioned to support our customers at every phase of the product life cycle. Our engineering breadth is just one of the many ways we can provide exceptional customer service and continue to be the best supplier in the market today.

The world's leading aircraft and aerospace engine manufacturers rely on Exotic Metals, and include:

• Airbus

• Collins Aerospace

• Gulfstream

• Honeywell

• Lockheed Martin

• Pratt & Whitney

• Rolls-Royce

• Safran

• Sikorsky

Manufacturing

Exotic’s desire to be the best was ingrained in our culture from the very beginning. Our founder built a superior titanium flange that he sold to the Boeing Company for 727 aircraft.

Since then, we have expanded our manufacturing capabilities from simple flanges produced using a hand-built press to complex assemblies, multiple types of welding, laser trimming, and machining. As we grew, Exotic Metals Forming developed the capability to perform many special processes in house, including heat treating and chemical cleaning, x-ray and non-destructive testing (NDT), tool design and fabrication, and testing.

Today, Exotic Metals Forming capabilities include the following:

• Axial load bulge forming – Produces complex shapes at room temperature

• Hydroforming – Room temperature, minimal thinning, repeatable

• Super plastic forming – Complex shapes used with specialized titanium alloys

• Laser cutting & drilling – Trimming, trepanning (holes), percussion drilling

• CNC machining – Close-tolerance, high-risk final machine operations

• Vacuum thermal processing/brazing – Joining two or more metals by melting a filler metal

• Welding – TIG (manual and automatic), resistance (spot and seam) robotic, orbital, plasma, laser, and weld inspection

• Chemical cleaning

• Robotic digital x-ray

• Fluorescent penetrant inspection/non-destructive testing

• Metallurgical lab

• Assembly

• Inspection

• Forming

To support our manufacturing operations, Exotic Metals Forming offers each customer:

• Dedicated program managers for both development and production programs

• Accredited quality system

• Reliable supply chain

• Hands-on operator training

Our proven experience, combined with expert manufacturing skills and vertical integration, make us an ideal partner for our customers' manufacturing needs.

Engineering

Our experienced and driven team of project, design, and manufacturing engineers are responsible for technical excellence from concept to full-rate production. Our project and design engineers provide technical leadership in proposals, project management, part design, design for manufacturing, analysis, qualification testing, manufacturing process development, tooling, machine design, and automation.

Our manufacturing engineers collaborate in these same technical leadership responsibilities with a healthy bias toward ongoing manufacturing process improvements and game-changing initiatives in support of full production readiness.

The Exotic engineering team works in concert with our dedicated in-house tool and die shop to deliver complete tooling and manufacturing equipment solutions. We utilize the latest in CADCAM software, including CATIA V4/V5 and Siemens NX9 for design work as well as ANSYS and NASTRAN/PATRAN for analysis, optimization, and design substantiation. Exotic Metals has original equipment manufacture (OEM) design authority for multiple aircraft systems and components, providing full system and component qualification testing in our in-house test lab.

We believe that our engineering staff is uniquely positioned to support our customers at every phase of the product life cycle. Our engineering breadth is just one of the many ways we can provide exceptional customer service and continue to be the best-value supplier in the market today.

Aircraft Services

Exotic Metals Forming offers a business unit dedicated specifically to support the airline and military users of our products, as well as aircraft and engine maintenance and repair operators.

Founded in 2002, Exotic Aircraft Services provides global support and is an FAA, EASA, and CAAC-certified repair station with the unique ability to fabricate spares to customer specifications, and provide FAA PMA spares under OEM license.

Typical products manufactured and repaired include engine bleed air ducting and manifolds, engine exhaust plugs and nozzles, APU bleed ducts and exhaust mufflers, cabin pressurization ECS ducts, waste tubes and other assemblies made from titanium, high-nickel alloys, and stainless steel sheet metals.

Certifications

• PRI Certificate of Registration

• FAA Operations Specifications

Capabilities

| Supported Platforms | ATA Chapters | |

|

The following lists some of the engine and airframe platforms we support: • Airbus A220, A320, A320neo, A330, A330neo, A340, A350, A380 • CFM International CFM56, LEAP • Embraer ERJ170/190 • GE Aviation CF34, CF6-80, GE90, GP7000, GEnx • International Aero Engines V2500 • McDonnell Douglas DC-10, MD-90, MD-11 • Pratt & Whitney PW2000, PW4000, PW6000, GTF • Rolls-Royce Trent 500, 700, 800, 900, 1000, RB211 |

We provide services across a number of ATA Chapters: • 21 – Air conditioning • 30 – Ice & rain • 36 – Pneumatics • 38 – Water/waste • 49 – APU • 54 – Nacelles • 71 – Powerplant • 72 – Engine • 73 – Engine fuel and control • 75 – Engine air • 78 – Engine exhaust • 79 – Engine oil • 80 – Engine starting |

In addition to performing OEM repairs and providing OEM-licensed spares, we develop alternate approved repairs and PMA spares. Please contact us for your particular requirement.

Exotic Metals "BEST" Guiding Principles

Be the best solution for our customers

• Who are my internal and external customers?

• Do I understand and deliver on my customers' wants and needs?

• Do I foster open, honest, and responsive communication with my customers?

• Will my customers want to come back to me?

Explore and innovate

• Do I ask if there is a better way?

• Do I actively seek opportunities to learn and share knowledge?

• Am I striving relentlessly to improve what we do and how we do it?

• Do the results optimize cost, quality, and delivery?

Stand for ethics and integrity

• Do I always do the right thing even when no one is looking?

• Do I treat people fairly, with dignity and respect?

• Do I hold myself and others accountable?

• Will others say I demonstrate a commitment to high ethical standards?

Train and sustain disciplines and controls

• Are my actions in alignment with procedures and control requirements?

• Am I aware of the implications of my actions?

• Do I demand competence and personal accountability of myself and others?

• Do others look to me for guidance?