O-Ring & Sealing Solutions Tools

Parker O-Ring & Engineered Seals Division specializes in the design and manufacture of high-quality sealing solutions. Our tools and resources are created for both novice and advanced users, providing the best sealing expertise and design recommendations for today's critical sealing challenges.

Tech Webinars

How to Read a Test Report

Originally hosted: February 22, 2022

Parker’s laboratory testing provides important data to help you select and compare material performance in a number of applications. To best understand the results, it is crucial to know what each test is measuring, the procedures that were used, and how the data was acquired. Join our experts to learn how to properly read a test report, what important values to review, and how those values are obtained to ensure proper material comparisons.

Extreme Low Temperature Sealing Solutions

Originally hosted January 11, 2022

Seals used in the aerospace and oil & gas markets are now being pushed to perform in temperature and pressure extremes never seen before in the rubber industry. Parker is meeting the challenge with it’s newest materials offering extreme low temperature performance alongside outstanding compression set resistance. Join us to find out more about these innovative materials and how they can help reduce downtime and cost in your critical applications.

Degradable Elastomers in Downhole Completions

Originally hosted March 23, 2021

Enhancing your Oilfield well completions results in a reduction of drill time, a safer work environment and cost savings for the operator. Discover degradable elastomer sealing technology offered by Parker.

USP Class VI Internally Lubricated EPDM

Originally hosted November 18, 2020

Parker's USP Class VI internally lubed EPDM is excellent for medical applications requiring low friction. Watch our replay to find out the benefits of using this dynamic sealing material.

Extreme Temperature Sealing

Originally hosted October 27, 2020

Discover the extreme temperature resistant sealing technology offered by Parker. This webinar goes into detail on the newest offerings, expanding temperature capabilities specifically with FKM and FFKM elastomers. Metal seals are also discussed in this recording.

Press-In-Place Sealing Technology

Originally hosted July 27, 2020

Press-In-Place (PIP) Seals ease component assembly, serviceability, and transit issues. Seal retention is the greatest benefit of using PIP seals, achieved by sidewall interference with no adhesives required. Discover the various custom profiles options and which applications they are best suited for.

Seal Failure Modes: Diagnosis and Solutions

Originally hosted January 23, 2020

Elastomeric seals provide the necessary barrier between your process and the environment. Leakage can occur when a seal is compromised, leading to unscheduled maintenance and costly downtime. At the worst, leakage can harm personnel or the environment. Identifying and preventing seal failure is critical to minimizing downtime and keeping the environment, health, and safety a top priority.

Electric Vehicle Battery Sealing

Originally hosted November 8, 2019

Large perimeter, extruded gaskets fill a critical sealing need in the electric and electrified vehicle industry. They provide a simple and reliable means of customizing a seal for each specific battery housing while avoiding the expense of dedicated tooling. Discover the innovative materials and custom sealing solutions we have to offer.

Web-based Apps & Training Courses

"How To" Videos

How to Utilize the O-Ring Handbook

How to Read a Test Report

How to Lubricate an O-Ring

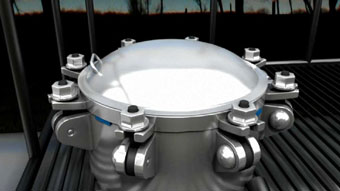

How to Install a Sure Torque Manway Gasket

How to Install a Diamond Seal

How to Install O-Rings: Dovetail Grooves

How to Install Hollow O-Rings

How to Install Female Radial O-Rings

How to Install Male Radial O-Rings

How to Install O-Rings: Face Seal Gland