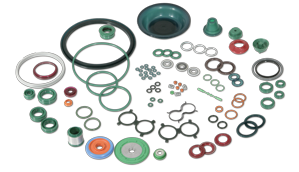

Sealing Solutions and Engineered Polymer Products

Even the smallest seal is a product with a huge responsibility: for human safety, the environment, reliable, energy- and cost-efficient operation, and long equipment service life. Parker Prädifa’s sealing solutions and engineered polymer products meet all of these demands in a variety of markets.

About Us

The Engineered Materials Group of the Parker Hannifin Corporation is the global leader in the field of designing, developing and manufacturing sealing systems, engineered components made from polymer materials, EMI shielding systems and heat dissipation materials.

In addition to standard sealing elements and sealing systems, the product portfolio encompasses a wide range of special profiles and geometries as well as other engineered components, in- and outside sealing technology. Furthermore, the Engineered Materials Group offers a variety of services such as testing, kitting, product identification and much more.

Fields of application range from mobile and stationary hydraulics, pneumatics, machinery and plant engineering, automotive engineering, the (bio-) chemical, pharmaceutical and medical (life sciences) sector, food processing, oil and gas, aerospace and semi-conductors through to electronics and telecommunications.

Special importance is always attached to the sustainability of the products and solutions in the interest of benefiting the customer and the environment through optimum energy efficiency, reliability, durability and economy.

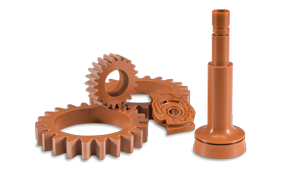

With strong in-house compound and design expertise, testing and process technology plus state-of-the-art manufacturing facilities the Parker Engineered Materials Group offers a wide portfolio ranging from standard products through to tailored new and system developments. The latter frequently result from close development partnerships with customers in keeping with Parker’s motto: ENGINEERING YOUR SUCCESS.

Product Portfolio

· Seals for Translatory Movement: Cylinder Seals

· Seals for Rotary Movement: Shaft Seals

· Diaphragms

· Energy Absorption: Damping Elements

· Specific sealing systems

· Rubber and plastic profiles

· Multi-component molded shapes and profiles

· According to customer specification

· Exclusive development

Engineering and Technology

Parker Prädifa draws on 60 years of experience in material science, process and manufacturing technology. Advanced product development includes computer simulation, prototyping for seals and an in-house chemical lab for development and testing of new compounds. The Prädifa Technology Division’s European manufacturing footprint consists of eight state-of-the-art facilities specializing in various product lines.

Material Development at Parker Prädifa

Our in-house chemical lab is the “cradle” of all Parker Praedifa sealing compounds. This is where our chemists develop, analyze and carefully test our new materials or modify our existing compounds to expand their application potential.

Product Development at Parker Prädifa

The video guides viewers through the development and design process of various sealing solutions while providing basic information on sealing technology as well as materials and designs.

Sealing Systems Put to the Test

Learn how the performance of a seal design can be subjected to exacting tests using state-of-the-art test rig technology and simulation, how damage analyses are carried out and much more.

Quality Management

Across the Entire Value Chain

Parker Prädifa has established market-specific Quality Management systems acc. to ISO 9001 / ISO/TS 16949 / EN 9100 / ISO 13485 / KTA 1401,BS OHSAS 18001 / ISO 14001 and uses APQP / FMEA / PPAP / FAIR / … quality methods.

An inspection plan for every product includes set-up inspection/in-process control (SPC) and (automated) final inspection using video projectors and video inspection machines, microscopes and a CAQ system.

Full traceability based on bag labels or shipping note is ensured and includes raw material batch, machinery, tools and operators.

Company Policy - Prädifa Technology Division

We are committed to compliance with all legal and other binding requirements in the area of environment, health and safety. We are committed to our employees, customers and partners as well as to the community in terms of health, safety, environmental and resource protection, and assume responsibility.

It is Parker's policy to comply with all applicable laws and other requirements and to consistently adhere to the agreements and contracts we conclude with our customers.

We seek to raise the quality of life through responsible, global stewardship.

We make sparing and careful use of natural resources and strive for maximum avoidance and reduction of waste, pollutant emissions and other environmentally harmful activities, above and beyond statutory requirements.

We include the aspects of energy efficiency and sustainability in the reviews of our processes and activities, and strive for continuous improvements in our energy-related and environmental performance as well as occupational safety. Our actions regarding the reduction of emissions are guided by the principle "Avoidance Before Reductions Before Compensation".

We take an interest in the environmental and energy-related concerns of all the parties in the communities we operate in.

We are committed to the consultation and participation of all employees and realize the value of our collective efforts. We believe our strength comes from the relationships and trust we establish with each other, our customers, suppliers, distributors and the world we serve.

We are committed to providing safe and healthy working conditions for the prevention of work-related injury and illness. We actively pursue a culture of continuous improvement in all areas of our business and in collaboration with our employees, customers, suppliers and distribution partners. This concerns internal processes as well as customer-focused processes and our environmental performance, including but not limited to sparing use of resources and utmost avoidance of activities with an adverse impact on the environment and the emission of greenhouse gases.

We train our employees and continue to develop their skills. We continuously share information about current topics from the areas of Quality, Environmental, Resource Protection, Health and Safety, and other relevant topics.

The satisfaction of our customers with our products and services is crucial.

We strive for zero defects and 100% target achievement.

In line with these goals, we define company-wide targets that we assign to individual organizational units. Together with suppliers and customers, we work on avoiding emissions that are harmful to the environment

We provide the resources that are required to achieve our targets.

We are committed to eliminate hazards and to reduce health and safety risks for our employees.

Procedures, policies and goals are formulated in writing with the objective of continuous improvement. Our carbon footprint encompasses Scope 1, Scope 2 and Scope 3. We review this footprint annually and derive emission-reducing measures.

We commit our employees and those acting on our behalf to compliance with these policies.

Business Continuity Plan Statement

Parker Hannifin´s Prädifa Technology Division is organized to quickly recover after a significant business disruption. To protect our employees and to resume operations as soon as possible, we have Business Continuity Plans and Disaster Recovery Plans for each of our operations in place. This ensures continuous service to our customers.

Our plans include emergency response teams, specific internal and external threat assessments, recovery strategies for critical functions, alternate facility management, alternate service provider management, critical supplier management, data security and data recovery management, emergency contact management, communication management.

Our plans are audited regularly and a rehearsal is performed on an annual basis.

Distribution

Global Presence, Worldwide Network, Local Competence

Parker is located in 49 countries around the world supporting 139 divisions with 341 manufacturing locations. Parker's unrivalled industrial distribution network extends to approximately 13,000 locations globally. Through this extensive network of local, independent businesses, Parker brings its products and services to customers in 104 countries.

Pressemeldinger

-

June 30, 2016