Aerospace / Military

Parker enjoys a long history of providing solutions designed to make today's complex systems safer, comfortable, and more efficient while lowering the overall costs of the life cycle. We work with customers to engineer dynamic sealing solutions that meet the reliability, safety, and supply chain challenges facing aerospace and military suppliers.

Airborne platforms include: Commercial aircraft, business jets, fixed wing, rotor, general aviation, space crafts

Military platforms include: Aircraft, tactical vehicles, weapons systems

Automotive & Transportation

Parker designs and manufactures high volume, quality seals for engines, braking, steering, and suspension in our automotive manufacturing sites which are certified to ISO 2001 and TS16949 requirements for quality management systems. Our manufacturing expertise, quality systems, and global footprint ensure the reliable delivery of quality products to meet customer demands.

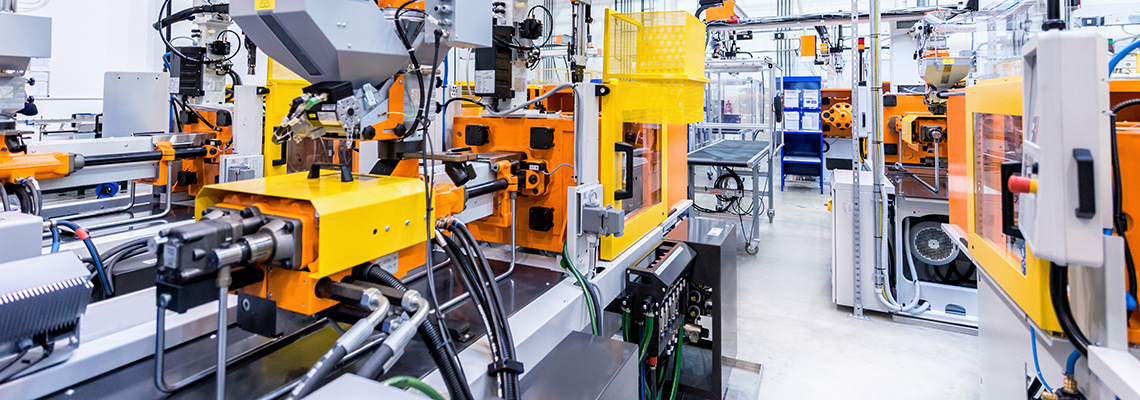

Industrial Equipment & Machinery

Parker Engineered Polymer Systems Division provides a diverse range of engineered sealing products and services for a broad range of applications for Industrial equipment, machinery and tools. We work with customers in supplying solutions that help move technology forward and keep pace with advances in machine design.

Our material science expertise enables us to provide innovative solutions for high and low temperatures, vacuum to high pressure, environmentally friendly fluids and aggressive media. We help engineer the success of equipment manufacturers.

Mobile Equipment

Working long hours and in the toughest and dirtiest of conditions, fluid power components in mobile equipment need rugged, long-lasting sealing systems to ensure reliability and optimal performance. When seals fail – progress halts.

We've upped the standard of "standard designs" when it comes to fluid power sealing. Parker's portfolio of seal materials includes a wide range of standard and enhanced formulation elastomers, non-filled and filled PTFE blends, and an entire family of tough, wear-resistant, high temp/high pressure, compression-set resistant Resilon® polyurethanes. We know sealing and have the design experience and material science expertise to meet the challenges of today's mobile equipment.

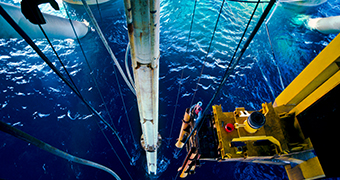

Oil & Gas

Parker designs and manufactures offshore & onshore solutions for marine riser, drilling, well servicing, frac and mud pumping, and completion. We also provide special services for Oil & Gas related companies which including kitting and logistics which simplify procurement and mistake-proof installation and assembly.

Parker's materials meet the rigorous demands of Oil and Gas service with high performance formulations suitable for environments exposed to aggressive media, extreme temperature and high pressure (HTHP) conditions. Our portfolio includes breakthrough, industry tested polymers, including: Elastomers resistant to H2S and sour gas, Resilon® Polyurethane, PTFE, Engineered plastics, PEEK, Molythane®, TPCE

Renewable Energy

Our products help solve the world's challenges in developing renewable energy solutions and promoting a clean environment.

We're working with customers and providing dynamic sealing solutions for wind, wave, and solar. We know a few things about performance, durability, scale and logistics. Contact us today to learn how we can work together to streamline product development.