FastSeal™ Assembly Instructions & Troubleshooting

Blog Posts

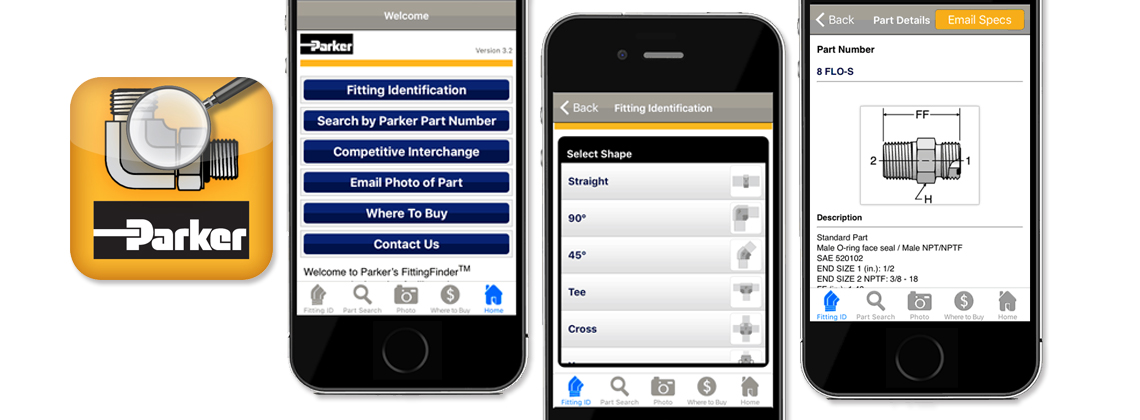

Parker FittingFinder App

Easily identify the part numbers of the Seal-Lok ORFS fittings and adapters that you need with our FittingFinder app. Dimensional information, CAD models, distributor locator, and a competitive interchange tool are all also included.

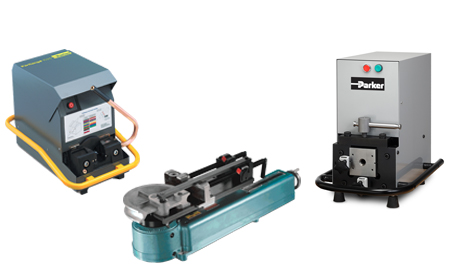

TFD ToolSpec Tube Fab App

Find the tube fabrication equipment and tooling part numbers that you need for the job with our TFD ToolSpec web app. For short-term and prototype projects, Tube fabrication equipment rentals are also available, and information is included on this site.

TFD TechConnect

Technical articles focused on hydraulic fitting topics, industry trends, and helpful hints from Parker engineers. Articles include topics such as thread identification, sizing tube for hydraulic system efficiency, tips for routing and clamping tube lines, recommendations on reassembling fittings, and many other helpful topics. Written by engineers for engineers, TFD techConnect is the go-to resource for engineers.

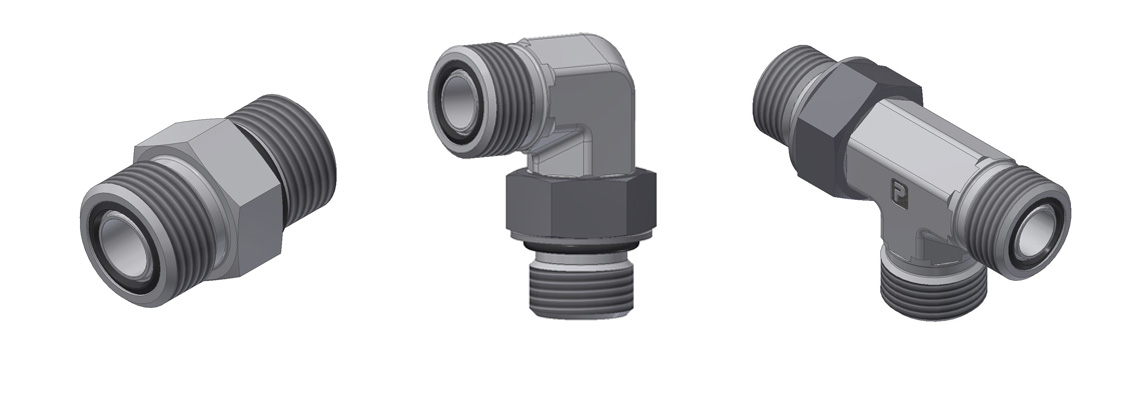

ORFS Fitting CAD Models

Need a CAD model of Seal-Lok O-ring Face Seal (ORFS) fittings or adapters for a system design or prototype drawing? Customers can easily search Parker's comprehensive library of CAD models available for download. These CAD models are available in a large variety of CAD formats. such as IGS, IPT, SAT, STP, and DWF to meet everyone's design needs.

Rapid Service Unit (RSU)

When time is of the essence and jobs depend on strict deadlines, Parker's RSU can deliver. Whether the part urgently needed is standard, an uncommon jump size, or a one-of-a-kind, RSU designs, produces and delivers high-quality hydraulic and pneumatic fittings and adapters to meet tight deadlines. Custom prototypes, pressure testing and tamper-resistant labeling are also available.

Downtime is further minimized with:

• Quick-response quotes

• Parts in hand in 24, 48, or 72 hours depending on customer needs

• No minimum orders

Custom Manufacturing

Parker knows that customers' requirements are always different. Custom manufacturing can transform a unique concept into a finished part, manufacturing to the customer's specifications, drawings, or world standard -- whether the need is for thousands or just one part. Offering different materials, plating, and seals based on the customer's application need is standard procedure for Parker.

Custom manufacturing offers:

• Design and manufacture of custom fittings

• Meets international standards in an ISO 9001 facility

• Ability to develop prototype products, and perform emergency repair and short run

Where to Buy

Need a hydraulic tube fitting or adapter, or tube fabrication equipment and tooling? Parker’s worldwide distribution network makes it convenient to get the parts you need, either over the phone or at one of our Parker Stores. Locate the distributor nearest to you.

Contact Us

Parker Hannifin Corporation

Tube Fittings Division

3885 Gateway Blvd.

Columbus, OH 43228

Phone: 614-279-7070

Email: TFD.support@support.parker.com

Live Chat

Have questions or need assistance finding something? Live chat is available most weekdays, 8am-5pm EST so you can talk to a division representative directly. We are here to help!